Wilhelm T & P is the right contact for consultation on systems in the textile industry. We have been working with leading international machine manufacturers for decades. This allows us to guarantee our customers the best quality and reliable service. We have been representing company Dornier successfully from 1994.

DORNIER is a trusted provider of customized weaving machines and equipment that produce high-quality fabrics. The company offers a system family consisting of gripper and air-jet weaving machines, as well as turnkey complete systems that are designed, engineered, and built according to specific customer requirements - all from one source.

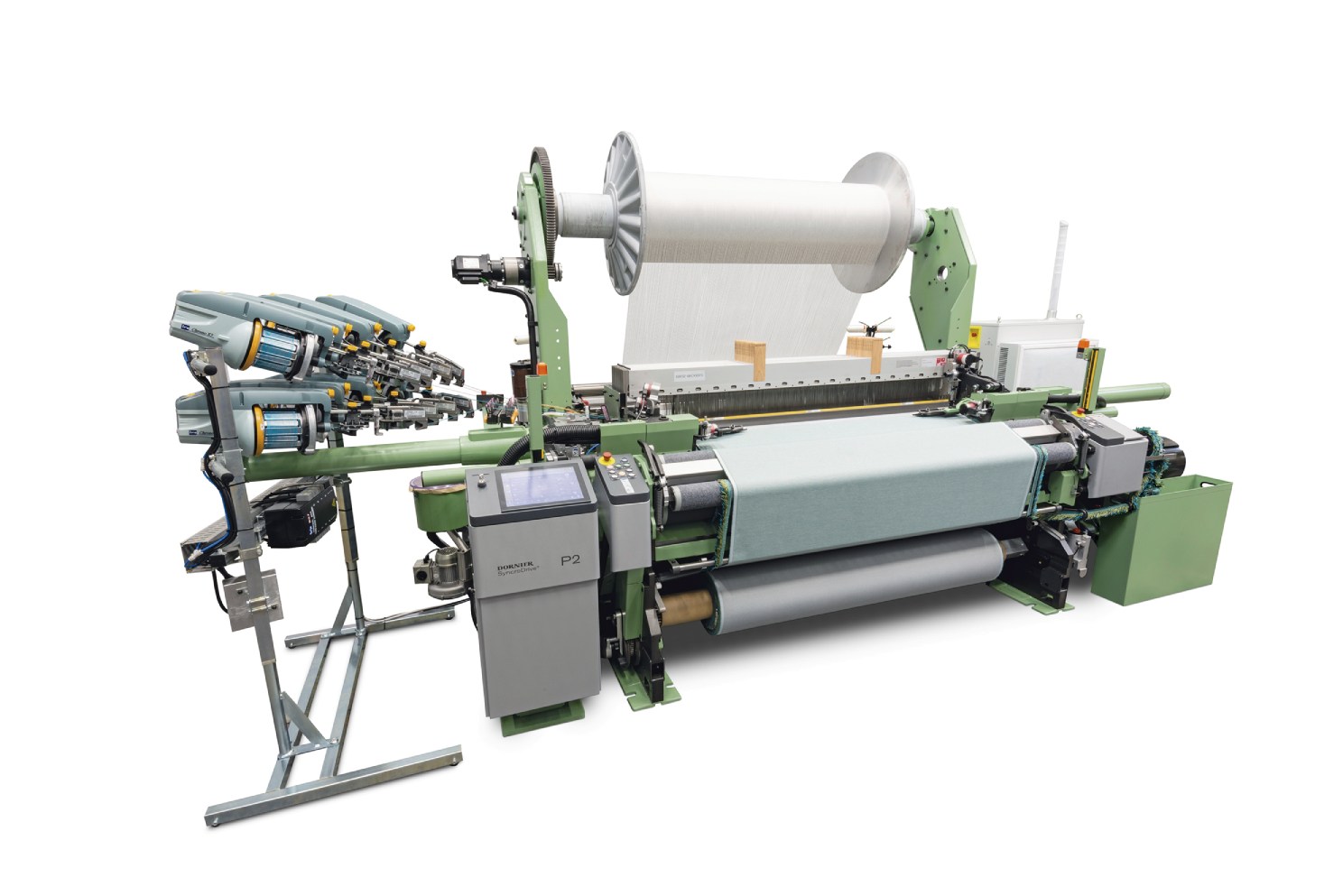

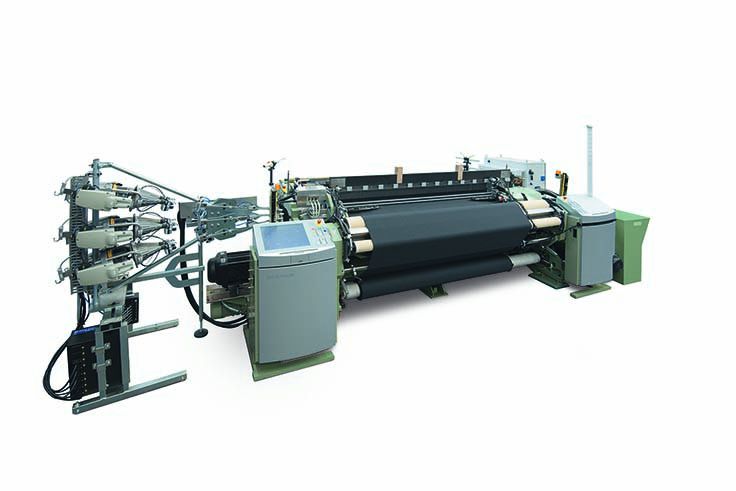

DORNIER P2 rapier weaving machine

The most flexible weaving machine in the world – made even better

The P2 is the result of almost 70 years of experience in the development and construction of weaving machines and serves as the successor to the P1 gripper weaving machine. With the P2, fabrics of the highest quality and efficiency can be produced, whether it's clothing, home textiles, or technical textiles made of glass, carbon, or aramid. The P2 is the most flexible gripper weaving machine in the world and is characterized by easy operability, unparalleled process reliability, and highest productivity.

The P2 can be used in combination with specialty devices such as eccentric, dobby (with up to 24 shafts), or jacquard machines (with up to 30,000 hooks). Additionally, it can be used in conjunction with DORNIER's developed EasyLeno® twisting system (with up to 16 weft colors). With a machine nominal width of 150 to 540 cm, the P2 is the perfect tool for creative, flexible, and precise production of fabrics of all kinds.

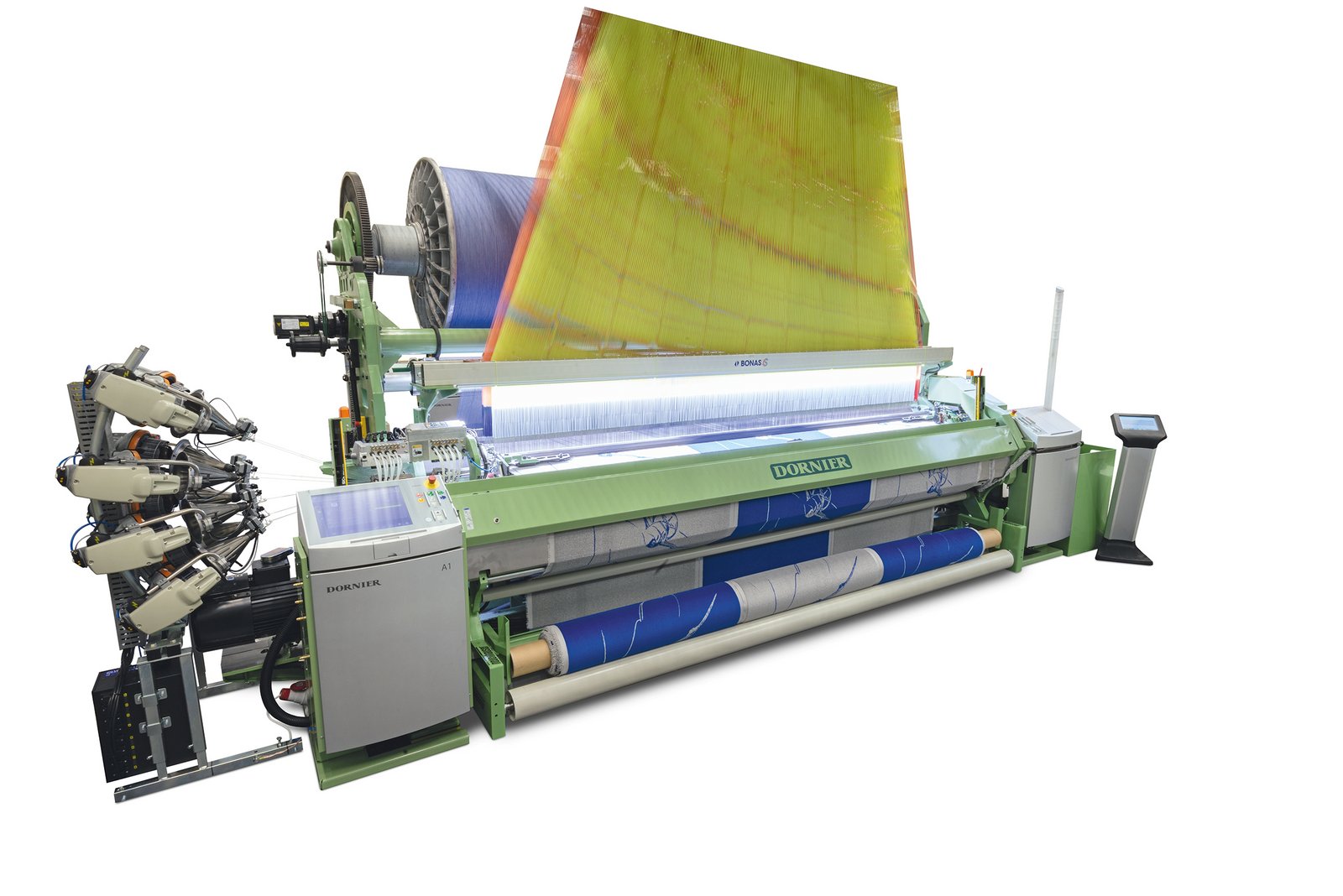

DORNIER A1

Productivity with the highest quality

The DORNIER air-jet weaving machine A1 is a multi-talent that offers innovative solutions for current and future web technical challenges. Based on the proven technology of the DORNIER system family, the A1 features a completely new control system and an application-specific drive concept based on three pillars.

The A1 offers an exceptionally wide range of applications and can be used in conjunction with eccentric, jacquard (up to 12,000 harness frames), or cam machines (up to 16 shafts), as well as the DORNIER EasyLeno® device. It is perfect for the creative, economic, and precise production of technical textiles, home textiles, and clothing fabrics with machine nominal widths from 150 to 540 cm.

Thanks to a variety of patented machine functions and components such as the DORNIER PIC® system with DORNIER ServoControl®-2 or the DORNIER PneumaTucker®, the A1 offers unparalleled process security for air-jet weaving machines. The article spectrum of the versatile A1 ranges from spinnaker silk, airbag, and conveyor belt fabrics to jacquard car seat covers in the technical textiles sector. In the clothing sector, wool, African damask, and functional textiles can be produced, while in the decorative fabric sector, multi-lane jacquard tablecloths and the finest curtains can be manufactured.