Wilhelm T & P is the right contact for consultation on systems in the plastics processing industry. We have been working with leading international machine manufacturers for decades. This allows us to guarantee our customers the best quality and reliable service. We have been representing company BritAs successfully since 2016.

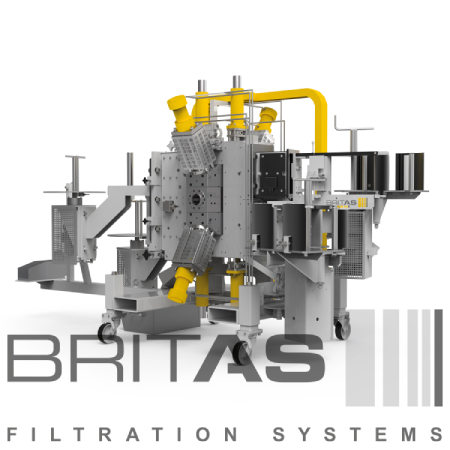

BritAS develops and builds equipment in two areas: one for filtering plastic waste and the other for producing machines to control the quality of plastic products. The latter ensure high quality rPellets through continuous measurements during production. BritAS' filtering systems enable efficient and cost-effective removal of high levels of contamination from plastic melts. This is achieved using automatic band-melt filters with a special technological concept.

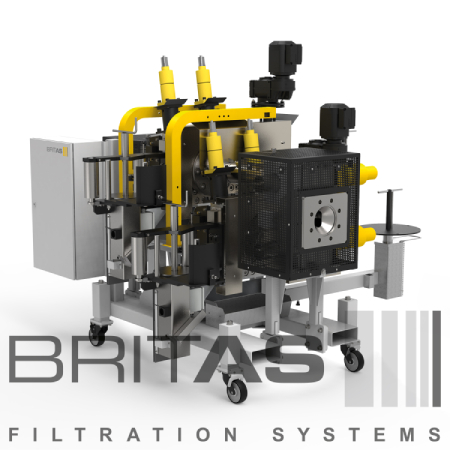

ABMF Automatic Belt Melt Filter

High regrind quality with low operating costs and full automation - that's what the Automatic Belt-Melt-Filter stands for. To effectively and efficiently filter contaminants from plastic waste, the BritAS filter automatically inserts a fresh sieve fabric with every filter change. This keeps the quality of the regrind consistently high, and the dirt is discharged from the machine with very low melt loss. The upstream extruder runs continuously with a buffer for the plastic melt.

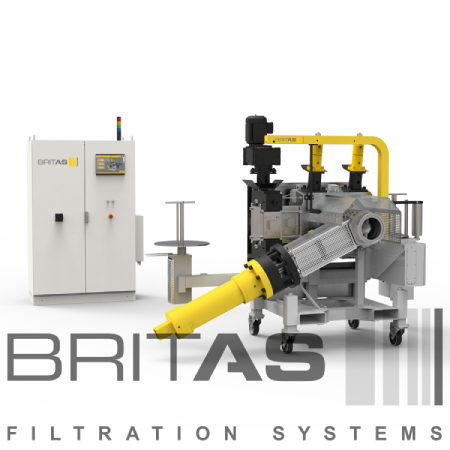

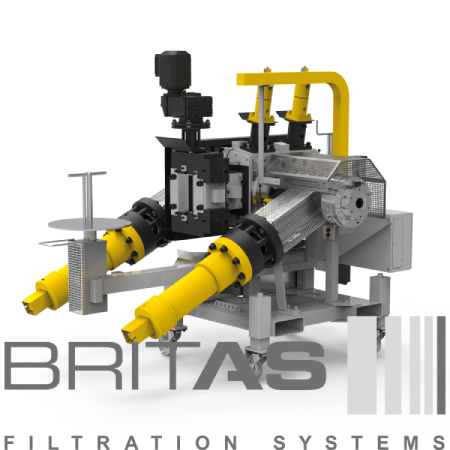

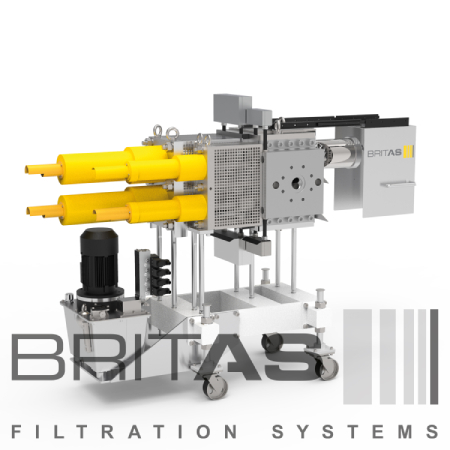

CMF Continuous Piston Screen Changer

The CMF continuous bolt screen changers are ideal for the filtration of industrial and production waste, especially in applications with high levels of contamination and frequent need for screen changes.

To meet these requirements, the continuous screen changer with backflushing CMF-BF is used, which is equipped with two backflushing bolts in a pre-module. This enables an automatic backflushing process.

During a filter change, one of the backflushing bolts is first moved into the backflushing position, interrupting the molten material flow of the corresponding filter. A small molten stream of the already cleaned material is diverted and passed backwards through the filter to be cleaned, before being discharged outward. This process is then automatically repeated for the second filter.